Views: 28 Author: Site Editor Publish Time: 2025-09-10 Origin: Site

When choosing a helmet, we often focus on the outer shell's color, the number of vents, or the brand name. Yet, tucked away inside is one of the most critical components for both safety and comfort: the helmet liner. This internal system is far more than just soft padding; it's an engineered assembly designed to manage impact forces, regulate temperature, and ensure a perfect fit. The importance of a helmet liner cannot be overstated, as it is the primary layer responsible for absorbing and dissipating the energy from a crash before it reaches your head.

The demands placed on a helmet liner vary dramatically depending on the sport. For a cyclist grinding up a hot mountain pass, the liner's primary performance metrics are moisture management and maximum ventilation. It needs to wick sweat away efficiently and allow air to flow freely to prevent overheating. In contrast, a skier carving down a snowy slope in frigid temperatures relies on their helmet liner for insulation and warmth, while also needing it to withstand the potential for multiple, lower-speed impacts during a session.

This article will guide you through the complex world of helmet liner materials. We will deconstruct the different layers, from structural foams to comfort fabrics, and explore the technologies that keep you safe. You will learn about the pros and cons of common materials like EPS and EPP, discover advanced structures like Koroyd®, and understand how these components are tailored to meet the specific needs of cyclists and skiers. By the end, you'll be equipped with the knowledge to choose a helmet not just for its looks, but for the advanced material science working to protect you.

At its core, a helmet liner is the system inside the hard outer shell that makes direct contact with your head. It performs several vital functions simultaneously.

A helmet liner is a multi-component system within a helmet designed to absorb impact energy, manage moisture and temperature, and provide a secure, comfortable fit. Its primary purpose is to decelerate the head during an impact, thereby reducing the forces transmitted to the brain.

The functions of a helmet liner can be broken down into four key areas:

Impact Absorption: This is the most critical safety function. The liner is engineered to compress, crush, or deform upon impact, converting the kinetic energy of the crash into thermal energy and slowing the head's movement over a fraction of a second.

Moisture and Temperature Management: The part of the liner touching your skin is designed to manage sweat and heat. In cycling helmets, this means wicking moisture away and promoting airflow. In ski helmets, it involves trapping a layer of warm air to provide insulation against the cold.

Fit and Comfort: A proper fit is essential for a helmet to be effective. The liner system, including adjustable dials and padding, ensures the helmet sits snugly and securely on the head without creating pressure points. This stability prevents the helmet from shifting during an impact.

Insulation: Predominantly for ski helmets, the liner provides a thermal barrier to protect the wearer from cold weather, wind, and moisture, ensuring comfort during long days on the mountain.

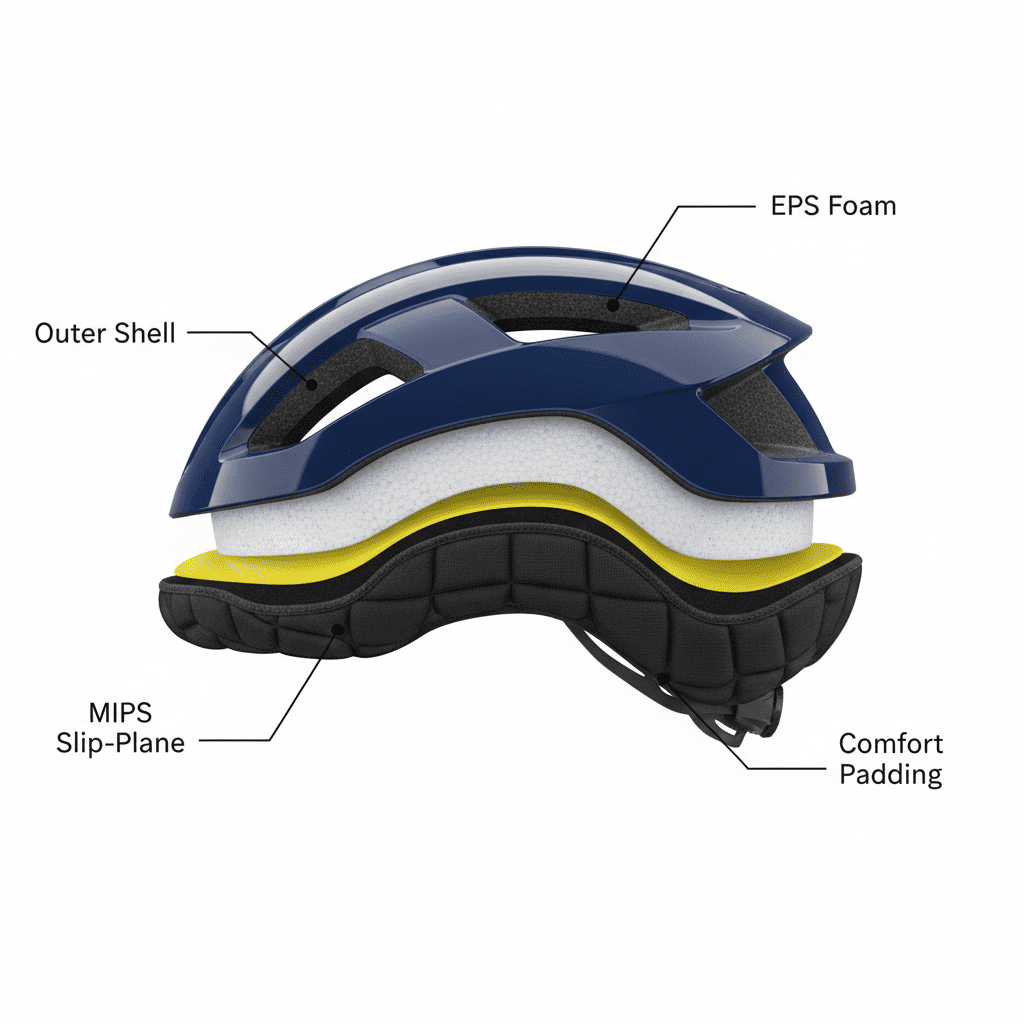

It's crucial to distinguish between the two main parts of the liner system: the structural liner and the inner padding. The structural liner is the thick layer of foam (like EPS or EPP) fused to the helmet's outer shell, responsible for impact absorption. The inner padding, or comfort liner, is the removable fabric layer that touches your head, focused on fit, comfort, and moisture management. While they work together, their materials and functions are entirely different.

The material composition of a helmet liner directly dictates its safety performance, weight, ventilation, and durability. Let's break down the most common and innovative materials used today.

Expanded Polystyrene is the most ubiquitous material used for structural helmet liners, having been the industry standard for decades. It is essentially a rigid, closed-cell foam made of tiny, fused plastic beads.

During an impact, the thin walls of these beads fracture and crush. This process of destruction is what absorbs and dissipates energy, preventing it from reaching your skull. It’s an incredibly effective method of energy management.

Advantages:

Lightweight: EPS is exceptionally light, making it ideal for performance-oriented helmets where every gram counts, especially in cycling.

Cost-Effective: It is relatively inexpensive to manufacture, which helps keep helmet prices accessible to a wider audience.

Proven Performance: It has a long and proven track record of effectively reducing head injuries in a wide range of impact scenarios.

Limitations:

Single-Impact Protection: The primary drawback of EPS foam is that its protective capability is based on permanent deformation. Once it has been compressed or crushed in an impact, it does not regain its shape or protective qualities. This means that after a significant crash, an EPS helmet must be replaced, even if there is no visible damage to the outer shell.

Expanded Polypropylene is a more resilient and flexible foam compared to EPS. While it also consists of fused beads, its chemical structure allows it to deform under load and then return to its original shape, a property known as elastic deformation.

This makes EPP a multi-impact material. It can withstand multiple lower-force impacts without losing its structural integrity, making it highly suitable for sports where repeated falls are common.

Advantages:

Multi-Impact Resistant: EPP can absorb energy from multiple impacts and still provide protection, unlike single-use EPS.

Durable: It is less brittle than EPS and can handle the general wear and tear of being tossed in a gear bag better.

Limitations:

Heavier and More Expensive: EPP is generally denser and more costly to produce than EPS, which is why it is typically found in higher-end helmets.

Suitability: It is most commonly used in ski, snowboard, and some mountain bike helmets where the likelihood of multiple, less severe impacts in a single day is higher.

Koroyd represents a significant departure from traditional foam liners. It is an advanced energy-absorbing technology constructed from thousands of co-polymer tubes that are thermally welded together to create a consistent, fully engineered core.

Upon impact, the Koroyd tubes crush in a completely controlled and efficient manner, absorbing maximum force and decelerating the energy from the impact. This structure is designed to be superior at managing both direct and angled impacts.

Advantages:

Advanced Energy Absorption: Koroyd structures can absorb more energy from an impact more efficiently than traditional materials within a thinner profile.

Superior Ventilation: The open-cell nature of the honeycomb structure allows air to flow freely through the tubes, providing exceptional ventilation and cooling, a major benefit for cyclists.

Lightweight: Despite its strength, Koroyd is incredibly lightweight.

Growing Popularity: Initially seen in niche, high-performance helmets, Koroyd is becoming more mainstream in premium cycling and mountain bike helmets due to its dual benefits of enhanced safety and superior airflow.

The comfort padding is the interface between the structural liner and your head. Its material composition is critical for long-term comfort.

Microfiber: A soft, plush material used for its comfortable feel against the skin.

Fleece: Commonly used in ski helmets, fleece linings provide extra warmth and insulation.

Coolmax® and other Wicking Fabrics: These are high-tech polyester fabrics engineered to draw (wick) sweat away from the skin to the fabric's outer surface, where it can evaporate quickly. This is a must-have feature for cycling helmets.

Antimicrobial Fabrics: Many liners are treated with antimicrobial agents (like Polygiene®) or are made from silver-infused threads to inhibit the growth of odor-causing bacteria, keeping the helmet fresh for longer.

Helmet technology is constantly evolving, leading to hybrid designs that leverage the strengths of multiple materials.

Combination Liners: Many modern helmets use a dual-density approach. For example, they might use a combination of EPS in most of the helmet for lightness, with strategically placed EPP inserts in high-impact zones for added durability. Others might combine an EPS frame with large Koroyd® panels to maximize both safety and ventilation.

Sustainability Trends: The industry is increasingly focused on sustainability. We are beginning to see the use of recycled EPS, as well as innovations with plant-based or natural fibers like flax, integrated into the liner structure to reduce environmental impact without compromising safety.

While safety is paramount, comfort is what enables you to wear a helmet for extended periods. The comfort features of a liner are specifically tailored to the intended activity.

Comfort for a cyclist is defined by three main factors: sweat management, ventilation, and weight.

Sweat Management and Airflow: During intense rides, the head generates a massive amount of heat and sweat. A cycling helmet's liner must feature advanced moisture-wicking fabric pads. The internal channeling of the structural liner is also designed to work with the vents to pull air across the scalp, actively cooling the rider.

Lightweight Design: A heavy helmet can cause neck fatigue on long rides. The use of lightweight EPS foam and minimalist padding helps reduce the overall weight, enhancing comfort over several hours.

Washable and Replaceable Pads: Given the amount of sweat they absorb, it's essential that the comfort pads in a cycling helmet are removable and washable. This allows for easy cleaning to maintain hygiene and prevent odors. Many manufacturers also sell replacement pad kits.

In skiing, comfort is synonymous with warmth, a seamless fit with accessories, and a snug feel.

Insulation and Warmth: The liner in a ski helmet is designed to trap body heat and provide insulation against cold and wind. Many feature full-coverage liners with plush, fleece-like materials and thick ear pads to keep the wearer warm in sub-zero temperatures.

Balance Between Comfort and Bulkiness: A ski liner needs to be warm but not so bulky that it feels cumbersome or causes overheating during strenuous activity or on warmer spring days. Many modern ski helmets now feature adjustable venting to help regulate temperature.

Liner Integration with Goggles and Ear Pads: A well-designed ski helmet liner ensures a seamless fit with goggles to eliminate the dreaded "goggle gap" on the forehead. The ear pads are also a critical component, providing warmth while often being designed to accommodate audio drop-in systems.

The liner is the single most important safety component in a helmet. Its performance is measured by its ability to manage impact forces and integrate with other safety systems.

As discussed, liners absorb impact by deforming. The material and density of the foam are precisely calibrated to crush at a rate that will slow the head's deceleration as much as possible. A foam that is too hard won't compress enough on smaller impacts; a foam that is too soft will "bottom out" or fully compress too quickly in a major impact, transferring the remaining energy directly to the head. Helmet manufacturers spend years researching and testing to find the perfect density and thickness for their intended use.

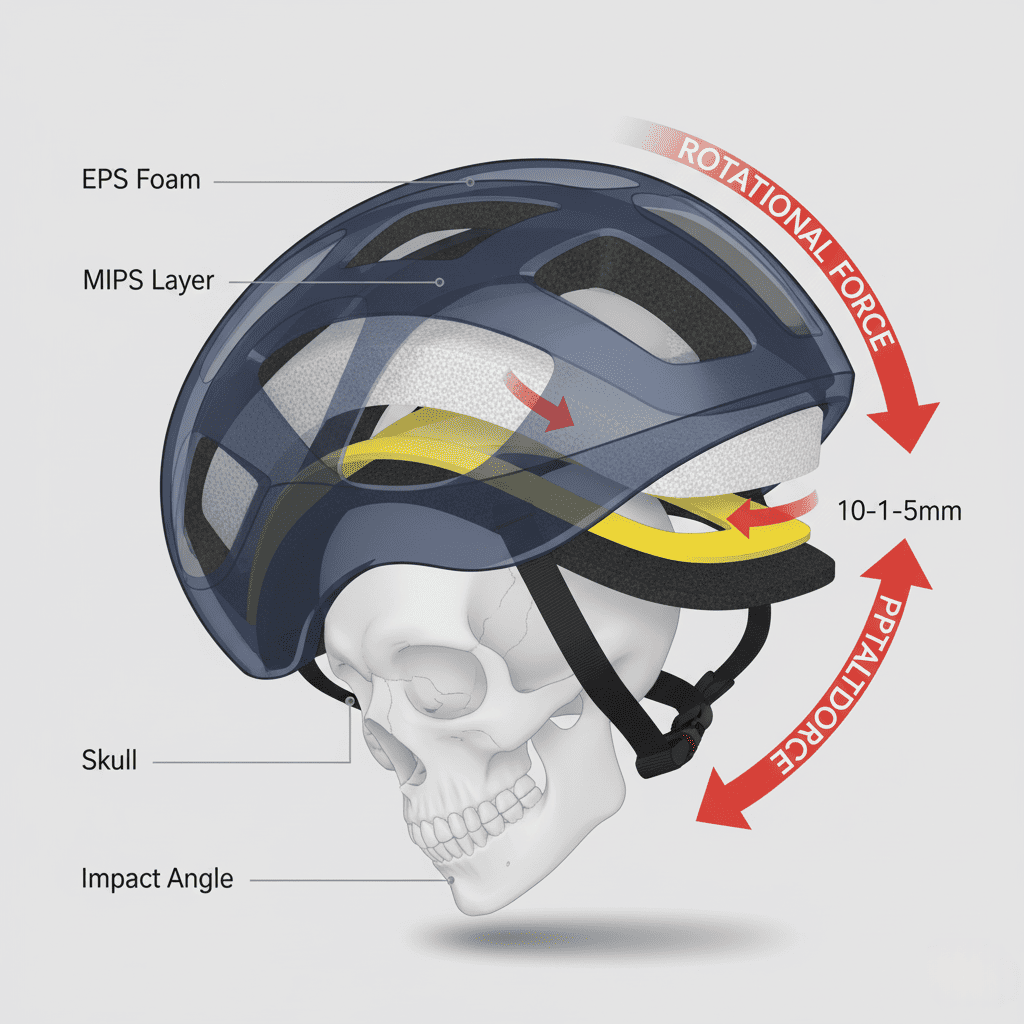

Most real-world impacts are not linear; they occur at an angle, which can cause the head to rotate violently. This rotational motion is a key contributor to concussions and other brain injuries.

MIPS is a low-friction layer, or "slip-plane," typically situated between the comfort padding and the structural foam liner (EPS/EPP). It is designed to allow the head to move 10-15mm relative to the helmet in any direction during an angled impact. This slight movement helps to redirect and reduce the harmful rotational forces that would otherwise be transmitted to the brain. The structural liner (EPS, EPP, Koroyd) is still responsible for absorbing the direct impact energy, while the MIPS liner specifically addresses rotational forces.

A helmet cannot be sold without meeting strict safety standards. These tests directly measure the performance of the liner. A helmet is subjected to a series of controlled impacts, and sensors inside a headform measure the G-forces transmitted through the helmet. The liner must reduce these forces to below a specified threshold to pass certification.

| Standard | Primary Region/Use | Key Focus |

|---|---|---|

| CPSC | United States (Cycling) | Rigorous impact testing for higher-energy crashes. |

| EN 1078 | Europe (Cycling) | Standard impact testing, also covers retention system strength. |

| ASTM F2040 | United States (Skiing) | Designed for snow sports, tests performance in cold conditions. |

| EN 1077 | Europe (Skiing) | Class A (full ear coverage) and Class B (soft ear coverage) standards. |

Proper care is essential to ensure your helmet's liner continues to perform as intended.

The rule for the structural liner is simple: replace the entire helmet after any significant impact. For EPS liners, this is non-negotiable. For multi-impact EPP liners, they should still be professionally inspected or replaced after a major crash or if they show any signs of damage.

The comfort liner (fabric pads) should be replaced for hygiene and fit reasons. If the pads become permanently compressed, lose their shape, or are damaged from repeated washing, they will no longer hold the helmet securely in place. Most manufacturers sell replacement pad sets.

Remove: Carefully detach the hook-and-loop-backed pads from the helmet's interior.

Hand Wash: The best method is to hand wash them in a sink with cool water and a mild soap (like baby shampoo or a gentle detergent).

Rinse Thoroughly: Squeeze and rinse the pads until all soap residue is gone.

Air Dry: Squeeze out excess water (do not wring them out, as this can damage the foam core) and let them air dry completely before re-installing. Do not put them in a machine dryer, as the heat can degrade the material.

Visually inspect your helmet's structural liner regularly. Look for:

Cracks or fractures in the foam.

Areas that look compressed or dented.

Any signs of the foam crumbling, flaking, or becoming brittle.

Discoloration or damage from solvents or improper storage.

If you see any of these signs, it's time to retire the helmet immediately.

Selecting the right helmet means matching its liner technology to your primary activity, environment, and priorities.

Sport Type: Are you a road cyclist who needs maximum ventilation, or a downhill mountain biker who might benefit from multi-impact EPP? Are you a casual skier or a park rider who falls frequently?

Climate: If you cycle primarily in a hot, humid climate, liners with Koroyd® and Coolmax® fabric are a top priority. For skiing in extremely cold regions, a liner with full fleece coverage is essential.

Budget: Helmets with standard EPS liners are highly effective and more affordable. Premium helmets with EPP, Koroyd®, or hybrid constructions offer advanced features but come at a higher price point.

Safety Certifications: Always ensure the helmet meets the appropriate certification for your sport and region (e.g., CPSC for cycling in the US). Features like MIPS offer an additional layer of protection against rotational forces.

| Priority Factor | Cycling Priorities | Skiing Priorities |

|---|---|---|

| Safety | Lightweight EPS for single major impacts. MIPS for rotational forces. | Multi-impact EPP for repeated falls. MIPS is also crucial. |

| Ventilation | Maximum airflow is critical. Look for large vents, internal channeling, and materials like Koroyd®. | Moderate, adjustable ventilation is key to avoid overheating without freezing. |

| Comfort/Fit | Minimalist, moisture-wicking, and washable padding. | Plush, full-coverage, insulating padding. Seamless goggle integration. |

| Durability | Less of a focus on liner durability, as the helmet must be replaced after one crash. | High priority. EPP liners offer better long-term durability against minor bumps. |

Are EPS and EPP liners washable?

No, the structural foam liners (EPS, EPP) are not washable, as water and cleaning agents can degrade the material. Only the removable fabric comfort pads are designed to be washed.

Do ski helmet liners keep you warm enough without a hat?

Generally, yes. Modern ski helmet liners are designed with high-quality insulation to provide sufficient warmth for most winter conditions, eliminating the need for a separate hat or beanie which can interfere with the helmet's fit.

Can I replace or upgrade my helmet liner?

You can and should replace the fabric comfort pads when they wear out. However, the structural impact liner (the EPS or EPP foam) is an integral part of the helmet's safety system and cannot be replaced or upgraded. If it is damaged, the entire helmet must be replaced.

Which liner material is best for hot weather cycling?

For hot weather, the best combination is a helmet with a highly breathable structural design, like those incorporating Koroyd® panels for maximum airflow, paired with high-performance, moisture-wicking fabric pads like Coolmax®.

Do premium liners really improve safety or just comfort?

Premium liners improve both. Advanced structural materials like EPP or Koroyd® offer tangible safety benefits, such as multi-impact protection or superior energy absorption. At the same time, high-end comfort liners use advanced fabrics and ergonomic designs that significantly boost comfort, reduce irritation, and manage sweat more effectively.

The helmet liner is a sophisticated and vital piece of safety equipment, engineered to do much more than simply cushion your head. From the single-impact, energy-absorbing crush of EPS foam to the multi-impact resilience of EPP and the advanced, breathable structure of Koroyd®, the structural liner is your first line of defense in a crash. Paired with advanced comfort fabrics that manage sweat for cyclists or provide crucial insulation for skiers, the complete liner system is a testament to modern material science.

Understanding the differences in these materials and how they are tailored for specific activities is key to making an informed choice. The right helmet is not just the one that fits your head, but the one that fits your sport. By prioritizing a liner system that matches your needs—be it ventilation for a summer ride or warmth for a powder day—you are making a critical investment. Investing in the right helmet ensures that you are not only protected by the highest safety standards but are also comfortable enough to perform at your best, ride after ride, run after run.

(+86)-755-27167380 / (+86)-138-2319-1080

info@reansonsports.com

(+86)-138-2319-1080